HDPE 90 degree elbow butt fusion fitting produced ......

-

AddressZheJiang, China

-

Phone+86-17367068772

-

E-mail[email protected]

Do Butt Fusion HDPE Fittings require additional protection to extend their service life?

Butt Fusion HDPE Fittings generally have a long service life due to their excellent material properties and connection process. However, in some special environments or use conditions, additional protective measures are indeed needed to further extend their service life and ensure the reliability of the system. The following is a detailed analysis:

1. Durability and potential risks of HDPE materials

HDPE (high-density polyethylene) is a high-performance plastic material with the following advantages:

Strong corrosion resistance: Good corrosion resistance to most chemicals (such as acids, alkalis, and salts).

Good wear resistance: Suitable for conveying fluids containing granular media.

Good low temperature resistance: Remains flexible in extremely cold environments.

Strong fatigue resistance: Can withstand long-term cyclic pressure changes.

Nevertheless, HDPE fittings may face the risk of performance degradation or damage under certain special conditions, such as:

Ultraviolet (UV) radiation: Long-term exposure to sunlight will cause material aging and reduce mechanical strength.

High temperature environment: Long-term exposure to high temperatures may accelerate material creep or deformation.

External mechanical damage: such as scratches, impacts or stress concentration caused by ground settlement during construction.

Chemical erosion: Certain strong oxidants or incompatible chemicals may damage HDPE.

2. Protective measures to extend service life

To address the above potential risks, the following protective measures can be taken:

(1) UV protection

Problem: If HDPE pipes are exposed to sunlight for a long time, ultraviolet rays will cause material degradation, resulting in surface cracking or strength loss.

Solution:

Use HDPE materials containing UV stabilizers (usually black HDPE, because carbon black is added as a UV protector).

Apply a UV-resistant coating or wrap a protective layer (such as aluminum foil or special UV protective film) on the outer surface of the pipe.

Try to avoid exposing HDPE pipes directly to sunlight, such as by burying them underground or covering them with sunshade facilities.

(2) High temperature protection

Problem: High temperatures may cause HDPE materials to soften or creep, especially when operating at high temperatures for a long time or near heat sources.

Solution:

Ensure that the operating temperature of HDPE pipe fittings is within its design range (usually not exceeding 60°C, and can reach up to 80°C for a short time).

In high temperature environments, choose HDPE materials with higher heat resistance (such as PE100 or PE100-RC).

Insulate the pipe, for example, using an insulation layer or insulation sleeve.

(3) Protection against mechanical damage

Problem: Scratches, impacts or ground settlement during construction may cause stress concentration, which may cause crack propagation or rupture.

Solution:

Strictly follow the specifications during construction to avoid scratches or other damage to the pipe surface.

When laying underground, use a sand cushion or protective sleeve to reduce external pressure and friction.

In areas with heavy traffic or places prone to impact, use reinforced HDPE pipe fittings or add an external protective layer.

(4) Protection against chemical corrosion

Problem: Certain strong oxidants (such as chlorine, peroxide) or incompatible chemicals may corrode HDPE materials.

Solution:

Before transporting special media, confirm the chemical compatibility of HDPE materials.

For environments where there may be a risk of corrosion, a protective coating can be added to the inner wall of the pipe or a multi-layer composite pipe can be selected.

(5) Antifreeze protection

Problem: In extremely cold areas, although HDPE itself has good low-temperature resistance, the medium in the pipe may increase expansion pressure due to freezing.

Solution:

In cold areas, insulate the pipe (such as wrapping with insulation cotton or using electric heating tape).

Ensure that the pipe system is emptied of the medium during downtime to avoid freezing.

Butt Fusion HDPE Fittings themselves have high durability and reliability, but in some special environments or usage conditions (such as ultraviolet exposure, high temperature, chemical erosion, etc.), additional protection measures are indeed required to extend their service life.

Product Display

-

HDPE 90 degree elbow butt fusion fitting

-

HDPE 45 degree elbow butt fusion fitting

HDPE 45 degree elbow butt fusion fitting produced ......

-

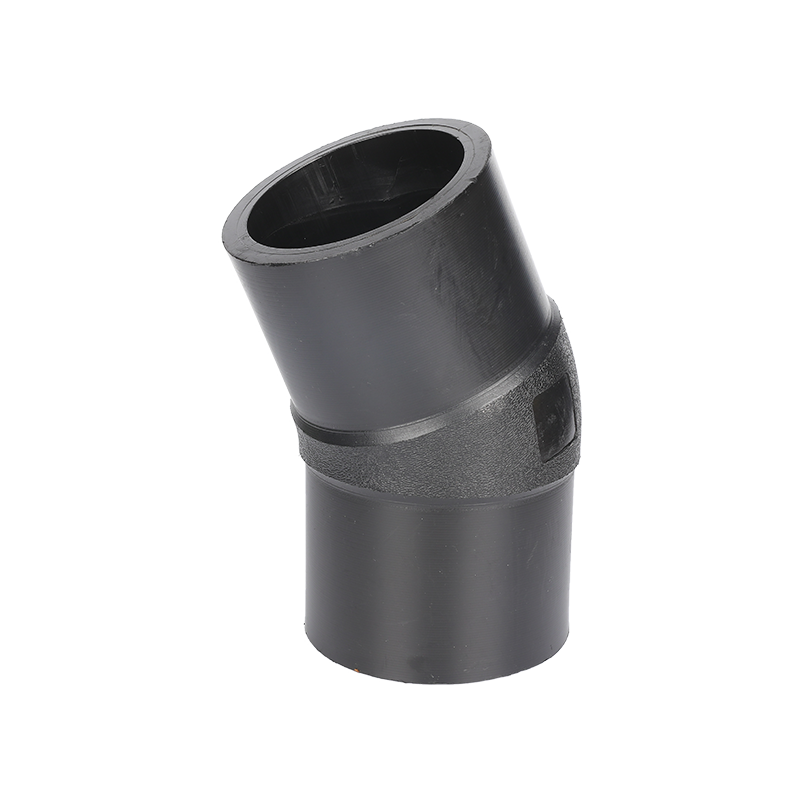

HDPE 22.5 degree elbow butt fusion fitting

HDPE 22.5 degree elbow butt fusion fitting produce......

-

HDPE equal tee butt fusion fittings

HDPE equal tee butt fusion fittings produced by in......

-

HDPE reducing tee butt fusion fitting

HDPE reducing tee butt fusion fittings produced by......

-

HDPE flange adaptor butt fusion fittings

HDPE flange adaptor butt fusion fittings produced ......

-

HDPE reducer butt fusion fitting

HDPE reducer butt fusion fitting produced by injec......

-

HDPE cross butt fusion fittings

HDPE cross butt fusion fittings produced by inject......

-

HDPE end cap butt fusion fitting

Mould injection hdpe end cap butt fusion fittings ......

-

PE/PPR socket fuison welding machine

PE/PPR socket fusion welding machine brief&fea......

-

Double U HDPE ground source pump fitting

Double U HDPE Ground source pump fitting produced ......

-

PIPE clamp HDPE ground source pump fitting

PIPE CLAMP HDPE Ground source pump fitting produce......

-

.jpg?imageView2/2/format/jp2)

Single U HDPE ground source pump fitting

single U HDPE Ground source pump fitting produced ......

-

U socket HDPE Ground source pump fitting

U socket HDPE Ground source pump fitting produced ......

English

English Español

Español русский

русский عربى

عربى

Contact Us