HDPE 90 degree elbow butt fusion fitting produced ......

-

AddressZheJiang, China

-

Phone+86-17367068772

-

E-mail[email protected]

How to ensure the durability of Butt Fusion HDPE Fittings in long-distance water pipelines?

To ensure the durability of Butt Fusion HDPE Fittings in long-distance water pipelines, the key is to adopt scientific methods and strict management in design, material selection, construction, installation and quality control. These measures can effectively improve the durability of the pipeline system and ensure that the fittings perform reliably in high-pressure, long-term water delivery applications.

High-quality HDPE materials are the basis for ensuring pipeline durability. HDPE has excellent resistance to chemical corrosion, impact resistance and environmental stress cracking. To ensure material quality, select HDPE materials certified to international standards (such as ASTM or ISO standards). The material needs to have high tensile strength and UV resistance, especially when exposed to sunlight for a long time or used in harsh environments, to ensure that the material can withstand the erosion of the external environment.

The welding quality of Butt Fusion HDPE Fittings directly affects the overall durability of the pipeline. During the welding process, it is crucial to control the welding temperature, heating time and butt pressure. Too high or too low temperature, insufficient heating time, and uneven butt pressure can all lead to welding quality problems, resulting in fragile welds, cracks, or leaks. Using automated or intelligent welding equipment can control these parameters more accurately to improve the stability and reliability of welding.

Strict quality control should be implemented during construction and installation. For quality inspection of welded interfaces, non-destructive testing (such as ultrasonic testing) can be used to ensure that the welds are free of defects such as voids or bubbles. Check the thickness and uniformity of the weld to ensure that the welding quality meets the design standards. In addition, construction personnel should receive professional training to ensure that they are familiar with the hot melt butt welding process and can perform the correct operating steps during construction, thereby reducing the impact of human factors on welding quality.

Even if high-quality welding is ensured during installation, pipes and pipe fittings may still be affected by stress or environmental changes after long-term operation, so regular inspections and maintenance are required. Especially in long-distance water pipelines, pipes are easily affected by environmental factors (such as temperature changes, geological movements, etc.). Regular inspections can detect any potential problems early, such as cracks in welds and leakage in interfaces. Timely inspection and repair can extend the service life of the pipeline and ensure its safety.

Long-distance water pipelines often pass through a variety of geological environments. When docking HDPE pipe fittings, the impact of different environments on the pipeline should be fully considered. For earthquake-prone areas or areas with subsidence risks, flexible connections or additional support facilities can be used to buffer the stress caused by geological changes. Although HDPE pipes are highly flexible, appropriate protection measures must be added around the pipelines during long-distance water transportation to avoid potential damage caused by geological changes.

Pipe fittings exposed to the natural environment for a long time may age due to oxidation and ultraviolet radiation. Therefore, adding antioxidants and anti-ultraviolet additives to the raw materials of HDPE pipe fittings can significantly improve the weather resistance and anti-aging ability of the pipe fittings. In addition, choosing an appropriate protective coating or burying the pipe underground during construction can also help reduce the impact of direct sunlight on the pipe, thereby extending its service life.

The pressure and flow rate in long-distance water pipelines also directly affect the durability of HDPE pipe fittings. Excessive water flow pressure will bring continuous stress loads to the joints of pipe fittings, which may cause cracking or loosening at the interface. Therefore, an appropriate pressure range should be maintained during pipeline design and operation. If pressurization is required, a pressure relief valve or buffer device should be designed in the pipeline to reduce the pressure on the fittings and ensure that the flow rate is within a reasonable range to prevent premature aging of the fittings.

The recorded data of each section of welding is crucial for later maintenance. During the construction process, the welding parameters, construction personnel and quality inspection results should be recorded in detail for reference in later maintenance. Data archiving can provide a basis for future fault analysis and maintenance, and can also help analyze the performance of pipelines in different environments and provide data support for subsequent installations.

Ensuring the durability of Butt Fusion HDPE Fittings in long-distance water pipelines requires starting from material selection, welding process control, quality inspection, environmental adaptability design and other aspects. Through a series of strict control and maintenance measures, the service life of HDPE pipe fittings in long-distance water delivery applications can be significantly extended.

Product Display

-

HDPE 90 degree elbow butt fusion fitting

-

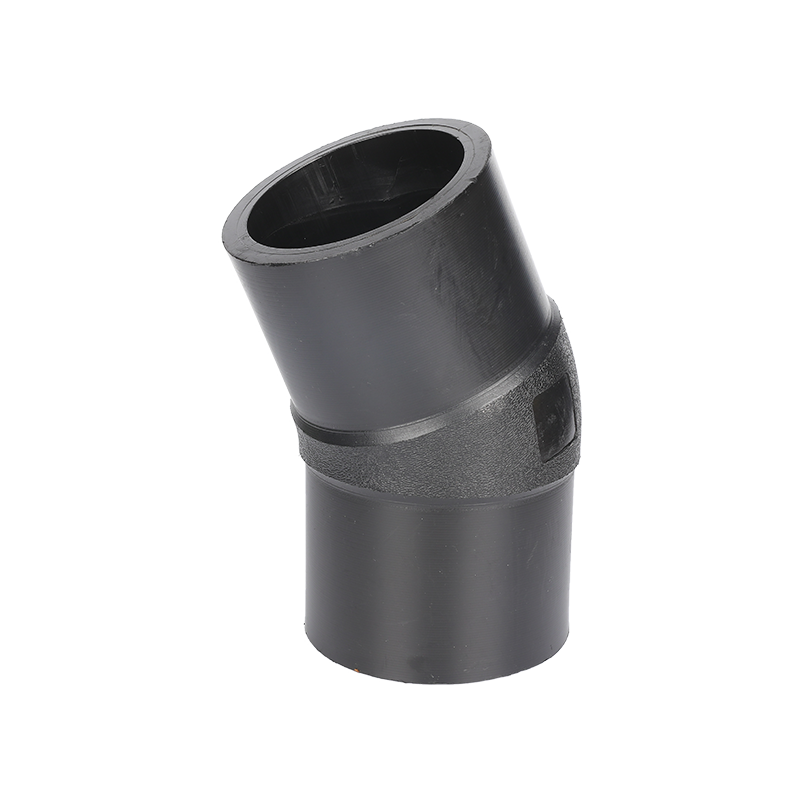

HDPE 45 degree elbow butt fusion fitting

HDPE 45 degree elbow butt fusion fitting produced ......

-

HDPE 22.5 degree elbow butt fusion fitting

HDPE 22.5 degree elbow butt fusion fitting produce......

-

HDPE equal tee butt fusion fittings

HDPE equal tee butt fusion fittings produced by in......

-

HDPE reducing tee butt fusion fitting

HDPE reducing tee butt fusion fittings produced by......

-

HDPE flange adaptor butt fusion fittings

HDPE flange adaptor butt fusion fittings produced ......

-

HDPE reducer butt fusion fitting

HDPE reducer butt fusion fitting produced by injec......

-

HDPE cross butt fusion fittings

HDPE cross butt fusion fittings produced by inject......

-

HDPE end cap butt fusion fitting

Mould injection hdpe end cap butt fusion fittings ......

-

PE/PPR socket fuison welding machine

PE/PPR socket fusion welding machine brief&fea......

-

Double U HDPE ground source pump fitting

Double U HDPE Ground source pump fitting produced ......

-

PIPE clamp HDPE ground source pump fitting

PIPE CLAMP HDPE Ground source pump fitting produce......

-

.jpg?imageView2/2/format/jp2)

Single U HDPE ground source pump fitting

single U HDPE Ground source pump fitting produced ......

-

U socket HDPE Ground source pump fitting

U socket HDPE Ground source pump fitting produced ......

English

English Español

Español русский

русский عربى

عربى

Contact Us